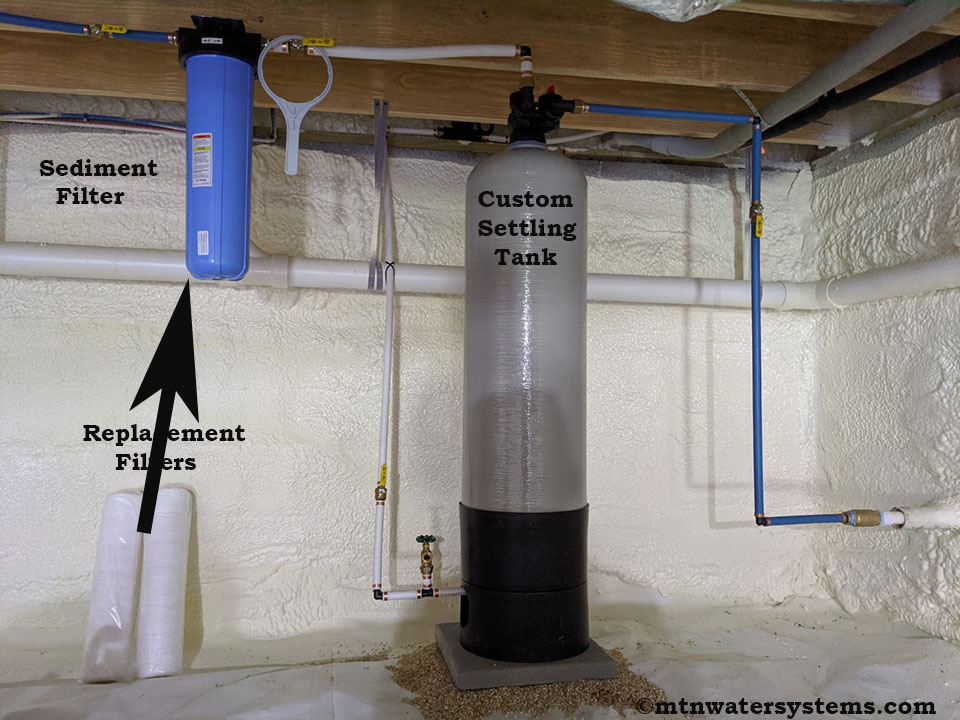

Settling Tank and Canister Filter for Sediment Issues

Sediment filters (Canister) are typically made from a porous material such as pleated polyester, string-wound polypropylene, or ceramic. As water flows through the filter, the filter material traps the sediment and particulate matter, leaving cleaner water to pass through. Sediment filters can be installed as a standalone unit or be part of a more extensive water filtration system that includes other filters. Regular maintenance of sediment filters is essential to ensure their effectiveness. Depending on the amount of sediment in the water, the filter will need to be changed or cleaned periodically to prevent clogging and maintain optimal performance. The interval in which the filter will need to be changed is dependent on the amount of sediment and the water usage. This can vary from daily to once every six months.

Settling Tanks are designed specifically for sediment, gritty, sand-like particulates, usually black or gray. Sediment will clog any small orifice and can cause fixtures and appliances not to work correctly. The settling tank works by allowing the water to flow through the tank. The sediment will settle to the bottom and will automatically purge when necessary. The settling tank does not have screens or filters that can clog up and cause pressure issues.

Mountain Water Systems has noticed increased sediment issues within the last few years in Western NC. This action led us to develop a better solution for removing sediment other than having canister-type filters or backwashing sediment filters. The canister filter replacements can get costly, depending on how often you have to change them. Also, if you have any iron, it will clog these filters even faster and cause flow restrictions. The backwashing sediment filters can help with small amounts of sediment. Still, sediment will tear up the seals inside the back-washing head. If the seals are torn and go unnoticed, this can cause premature failure of well water pumps.